Process reliability in tube production

17 Apr 2024

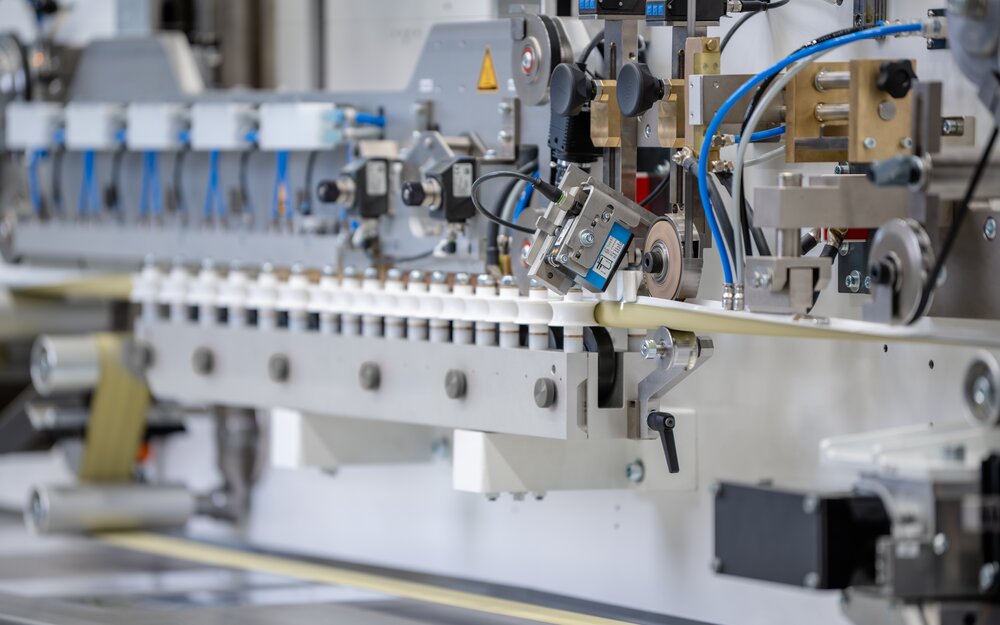

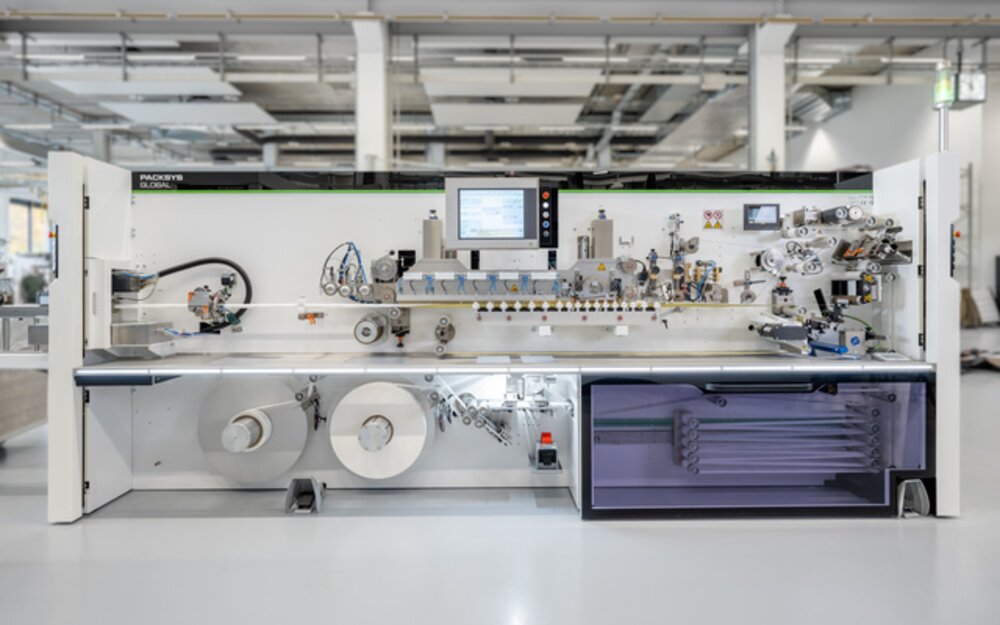

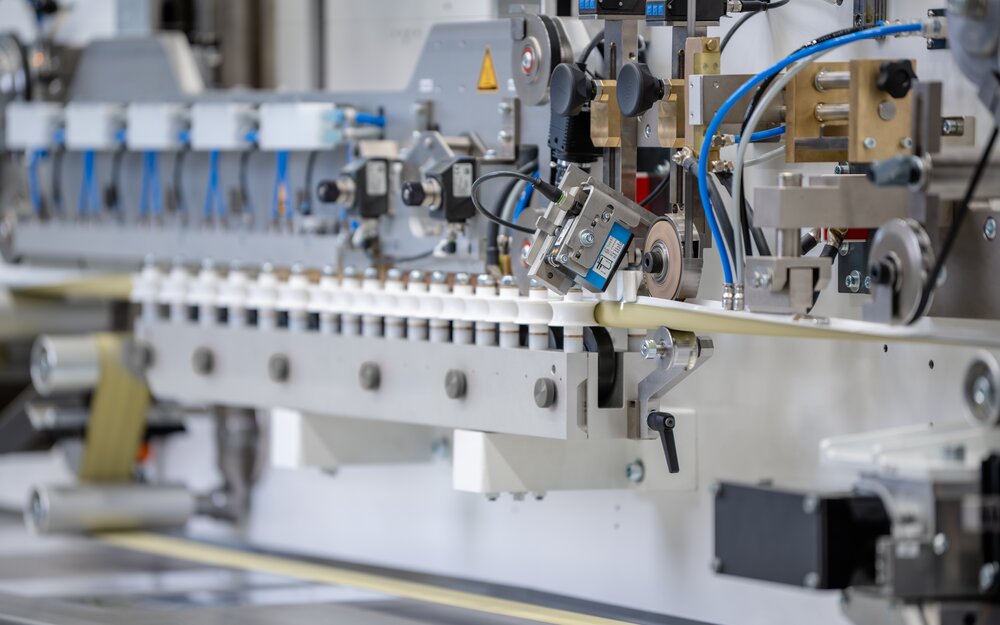

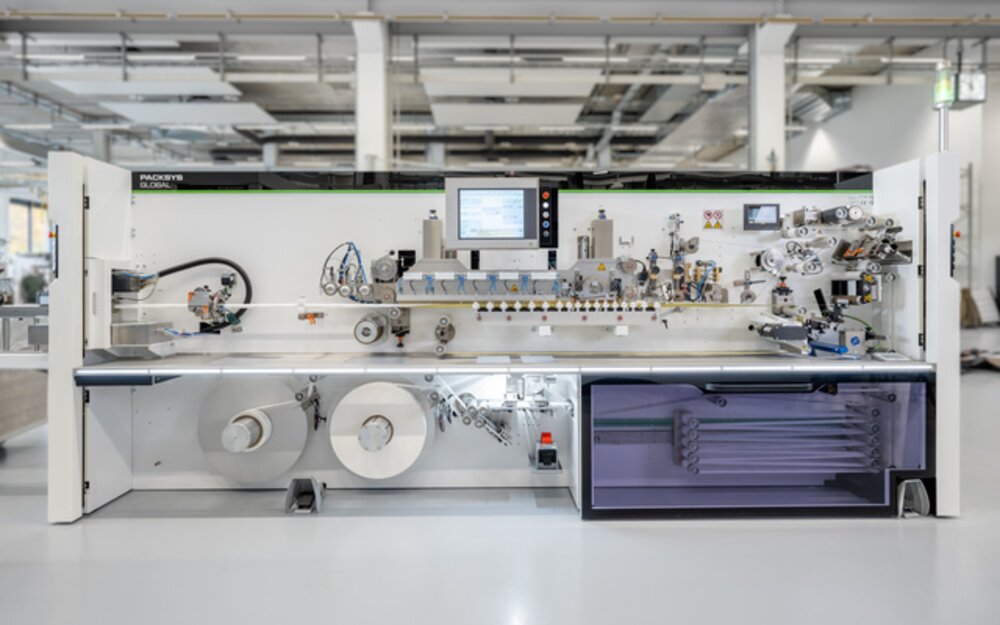

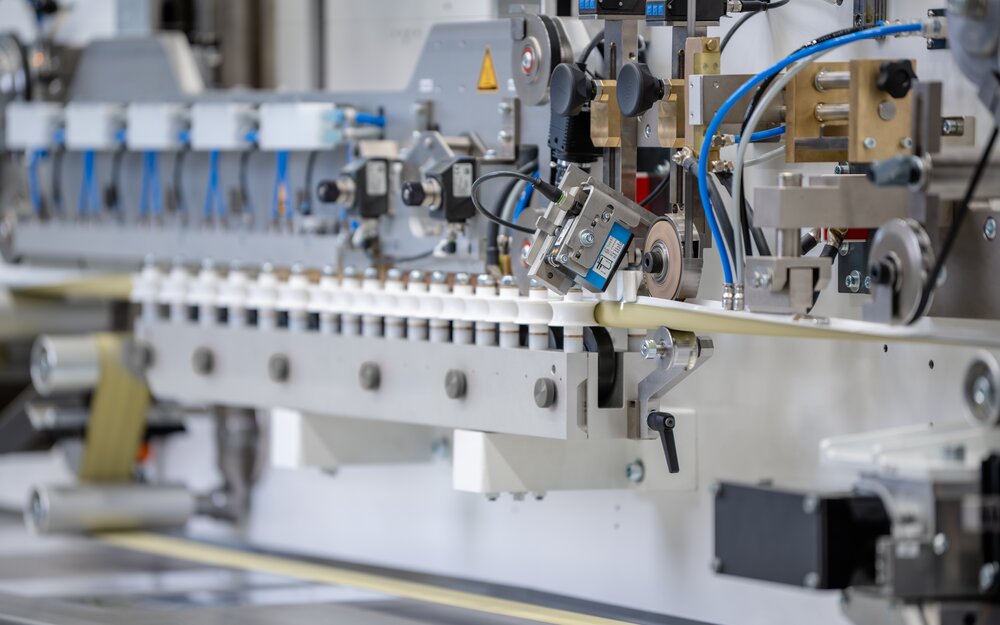

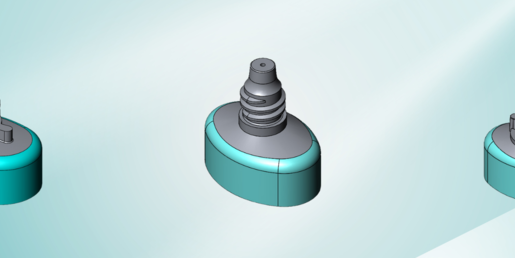

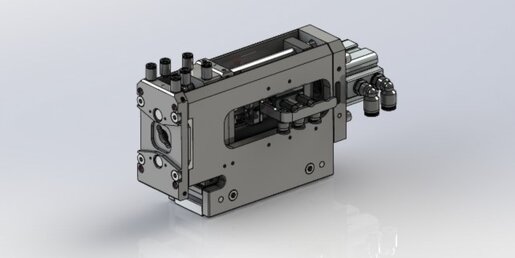

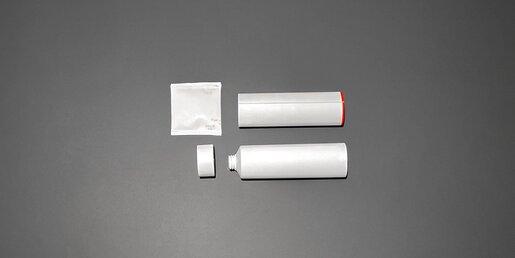

To optimise tube production and ensure process reliability, we rely on advanced technology. Our FlexSeamer side seamer machine is now equipped with digital position indicators from SIKO. These enable precise and monitored changeover to different tube formats (format adjustment).

Efficiency, high output and user-friendliness are our top priorities. A crucial aspect of process reliability is the correct adjustment of the machines to different tube formats. Conventional mechanical position indicators require manual adjustment of these formats, which carries a high risk of error. The effects of an incorrect setting are often only revealed when the products are subjected to destructive random testing, which is very time-consuming. To simplify this process and increase reliability, we have integrated SIKO's monitored changeover solution. This eliminates the need for subsequent quality checks. By working with SIKO, the renowned German specialist in sensors and positioning systems, we can offer our customers a reliable and user-friendly solution.

For more details and technical advantages, please read the article "Process reliability in tube production".