Making the most out of your equipment

With a passion for precision and perfection, we offer premium Swiss quality service and ensure your equipment runs at maximum productivity. To optimize the performance and profitability of equipment, we apply a variety of proven and new technologies. We are continually developing our range of products to enhance existing machine designs, providing even greater quality and output.

Enhance Machine Productivity

You can recover the cost of your upgrade in as little as six months while you continue benefit from new technologies for years to come. Our personalized training is designed to maximize machine productivity and achieve premium product quality.

Topics include:

- Optimizing control parameters

- Troubleshooting

- Equipment/Line overview

- Optimizing hardware adjustments, etc.

Customized solutions

PackSys Global is offering you a free machine assessment service that could identify you solutions to maximize your tube production output and maintain premium tube quality. Our engineers will visit your premises and inspect your PackSys Global machine and its performance. We will then recommend our solutions, which will be tailored to your needs and expectations as well as take into account the present state of the machine.

Your Benefits

- Achieve premium product quality

- Maximize production output

- Maximizing process reliability

- Reduce production costs

Machine overhauls and upgrades

The use of modular retrofit kits allows PackSys Global to quickly upgrade and customize your machine in order to step up its output and at the same time enables you to take advantage of our state-of-the-art technologies to improve the process stability as well as product quality.

Automation and software upgrades

Optimized control settings, latest software updates, and new solutions such as “EagleOwl” remote access ensure safety and operational reliability, and reduce downtime.

Our proven expertise

Our trained and qualified field engineers have performed overhauls on a large number of PackSys Global machines, some of which were already 30 years old. We will live up to the trust you place in us.

Shorter payback period

You can recover the cost of your upgrade in as little as six months while you continue to derive the benefits of new technology for years to come.

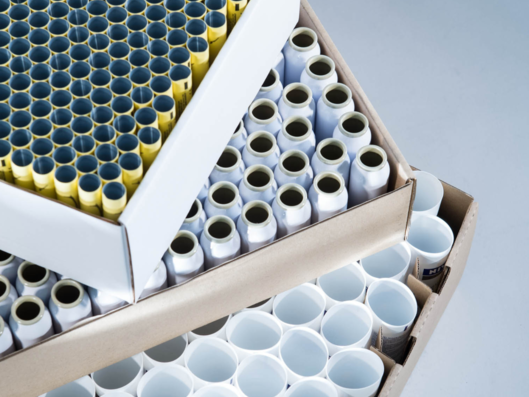

Size Parts & Pilot Testing

Your new tube design

Either you are in need of new size parts or special pilot tooling for function test or to promote new cosmetic tube design. We are the right partner. With over 40 years of experience we can actively support you with new developments and sophisticated designs.

The Technology

The cosmetic and personal care industries are the main drivers for new developments in tube designs and tube manufacturing. These tubes play a critical role in product:

- Presentation

- Differentiation

- Protection

- Application

The tube, being recognized as the perfect packaging for viscous products, is also used for a growing number of new products like mascara, lip balm, and applications like precision dosing, nasal applicators or dome heads.

Customers look for marketing differentiations such as best decoration, special tube design (oval, rectangular), attractive caps aligned with tube decoration and much more – and all this at the best possible price with decreasing volumes.

Whatever kind of plastic or laminate tube your customer or your marketing people ask for, we have the best choice to provide the required production equipment.

You can recover the cost of your upgrade in as little as six months while you continue benefit from new technologies for years to come.

| Assessmet | Our Proven Expertise | Shorter Payback Period |

|---|---|---|

| Our engineers will visit your premises and inspect your PackSys Global machine and its performance. We will then recommend our solutions, which will be tailored to your needs and expectations as well as take into account the present state of the machine. | Our regularly trained and qualified field engineers have performed overhauls on a large number of PackSys Global machines, some of which have been in operation for 30 years. We will live up to the trust you place in us. | You can recover the cost of your upgrade in as little as six months while you continue benefit from new technologies for years to come. |

Your Benefits

- Achieve premium product quality.

- Maximize production output.

- Maximizing process reliability.

- Reduce production costs.

Download

The Slitting / Folding Pilot Machine

The SFP machine is a single station pilot machine to simulate processes identical to our complete slitting and folding machine portfolio.

PackSys Global has such a machine available in the lab for customers who need to do pilot testings on new closure developments. Within short time, functionality and performance of both new developments or modifications on exiting closure designs could be completed with manufactured closures on the Packsys Global’s lab machine.

Your Benefits

- This single station machine is suitable for smaller batches for new closure design developments for line trials.

- Easy adjustments to the industry needs for various slitting settings and folding process parameters.