Pearl Tube - the shimmering innovation

18 Jan 2024

Huhtamaki once again has relied on our expertise and machines to test and refine its latest mono-material tube laminate innovation, this time without an EVOH barrier. The result is a tube of outstanding quality with an ultra-thin barrier layer of less than 1µm. blueloop tube one.

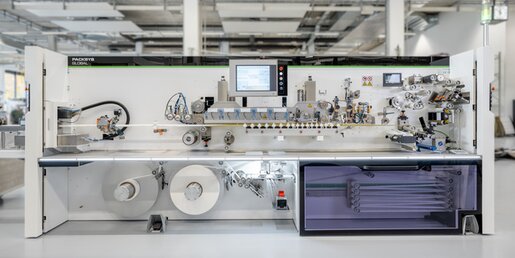

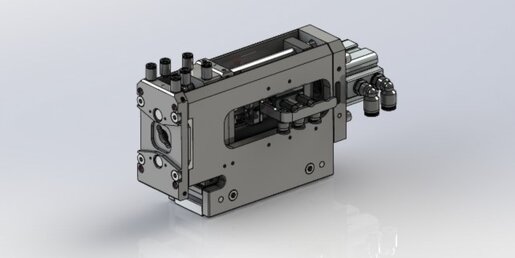

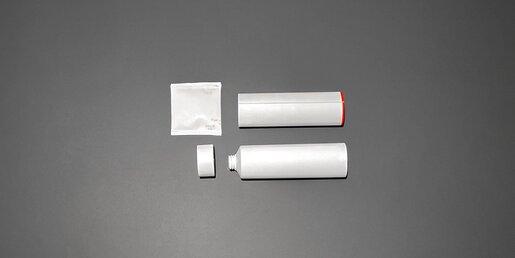

The Pearl Tube is not only aesthetically pleasing, it also sets new technological standards. Huhtamaki's innovative blueloop tube one laminate, printed by Elpes (www.elpes.com), was put through its paces on our FlexSeamer side-seamer machine in our KREALab. blueloop tube one offers improved stiffness and barrier properties, high opacity and excellent printability. The challenge was to avoid damaging the ultra-thin barrier layer during the seaming process. However, the tests and subsequent barrier measurements showed that a perfect barrier function could also be achieved in the area of the side-seam. As a result, the FlexSeamer, as well as all other PackSys Global side-seaming machines, are ideally suited to process the blueloop tube one laminate. Our FlexSeamer was used to achieve a perfect barrier seam.

The blueloop tube one laminate is available in 220μ and 300μ and in white or silver. Thanks to its RecyClass certification, blueloop tube one helps reduce the environmental footprint and sets an example for environmentally conscious packaging solutions.

The benefits of blueloop tube one laminate at a glance

Innovation

- Very thin barrier layer, which, thanks to Huhtamaki's production technology, is well below 1µm.

- The higher percentage of PE in the laminate, compared to an EVOH containing laminate of the same thickness, allows for a higher classification of the laminate which can mean lower „plastic taxes“.

Sustainability

- blueloop tube one is a mono-material laminate which is recyclable in the rigid HDPE stream

- The reduced thicknesses of the blueloop tube one structures enable material savings of up to 37%.

Material properties

- blueloop tube one tube laminate offers excellent emptying properties, stiffness comparable to standard materials and very high opacity.

Very high barrier solution

- The ultra-high barrier tube laminate allows tubes to meet special requirements and is an ideal choice for products for oral care and other personal care products.

Material structure

- blueloop tube one heralds a new era in process technology for ultra-high barrier tube laminates without EVOH barrier.

Our collaboration with Huhtamaki and Elpes has not only resulted in a superior tube but has also pushed the boundaries of tube manufacturing.

Do you have any questions about the Pearl Tube, or would you like to know more about processing blueloop tube one? We are here to help.